ICT for Sustainable Manufacturing Group

The overall goal of sustainable manufacturing is to obtain a holistic view of product cycles in the manufacturing industry and optimise the life-cycle of manufacturing systems, products and services.

Methodologies and tools to support the manufacturing of products and production must be increasingly life-cycle and service oriented, in addition to the requirements for quality, cost- effectiveness, safety and cleanliness.

Research

Closed Loop Lifecycle Management — CL2M

Our vision in ICT4SM Group includes the development of a Closed Loop Lifecycle Management (CL2M) system based in Industry 4.0 technologies that allow Product Information Tracking and Flow Management.CL2M will allow all actors that play a role during the lifecycle of a product (managers, designers, service and maintenance operators, recyclers, etc.) to track, manage and (…)

Zero Defect Manufacturing — ZDM

One of the most promising strategies today is called Zero Defect Manufacturing. This strategy has the goal to decrease and mitigate failures within manufacturing processes and ‘to do things right in the first time’, in other words to eliminate defected parts during production. The Zero Defect Manufacturing can be implemented in two different approaches. The (…)

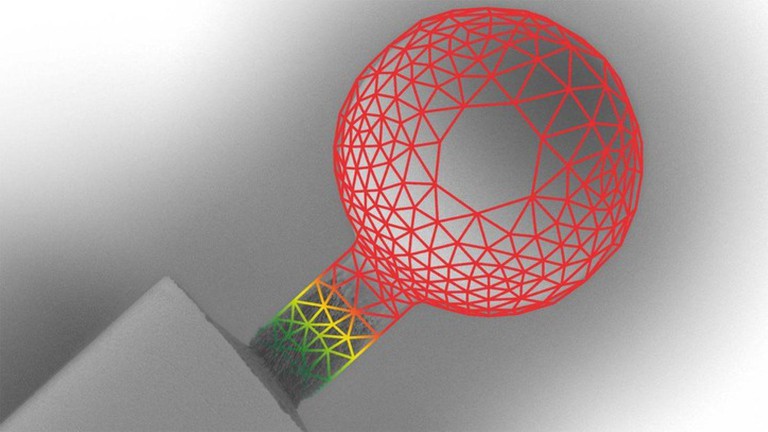

Digital & Cognitive Twins

Digital Twins (DT). A DT is a digital duplication of entities with real-time two-way communication enabled between the physical and cyber spaces. It aims to support integration of IoT for connecting the physical and virtual spaces. In the illustrated case the physical twin is defined as an areo-engine, the virtual entities of areo-engine include CAD (…)

News

Contact

Head of ICT4SM: Professor Dimitrios Kyritsis

Administrative assistant: Sylvia Widmer

—

EPFL SCI-STI-DK

ME A1 392 (Bâtiment ME)

Station 9

CH – 1015 Lausanne